Technology > Assembry fablication process

One stop operation is done for assembly/fablication/electric test of 100kW-3000kW class rotor and stators.

Hotta Electric's special skillTechnology

Special technical list

Because it is Hotta Electric, it is a one-stop production system. It can also cope with small volume production according to customer's needs.

Special technical list

| ※For other services please contact us. | |

|---|---|

| Machining / welding process | It corresponds to conductor processing and various welding processing of various connecting parts mainly for parts for electric generators, electric motors and vehicles. |

| Winding Forming process | We can deal with winding/forming of the stator coil for rotary machines by round wire/rectangular wire as well as winding automatic insulating tape wound to the flat rectangular conductor for rotor coils, cutting forming, and machining with a radius. |

| Insulation process | Each type of Insulating tape is wound by a machine in a form of a line/a coil. As for complex from parts, do it manually. |

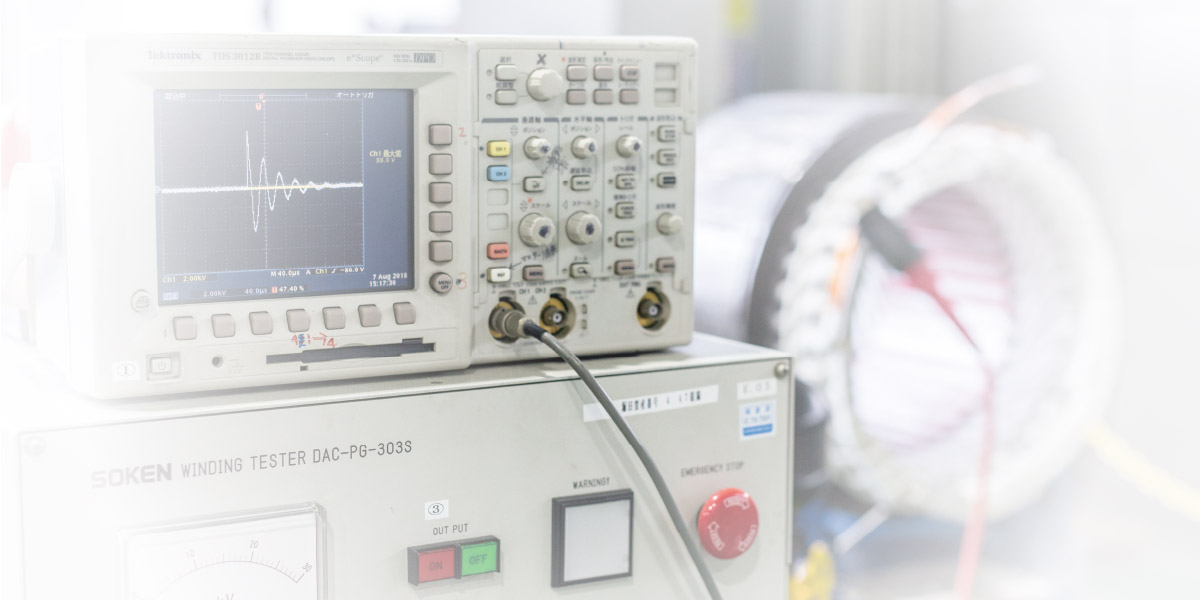

| Assembly fablication process | One stop operation is done for assembly/fablication/electric test of 100kW-3000kW class rotor and stators. |